3M Cubitron II

With decades of experience in ceramic, abrasive and microreplication technologies, 3M reinvented abrasives with 3M™ Cubitron™ II Products. The secret lies in the revolutionary precision-shaped ceramic grain technology pioneered by 3M. As the triangular shaped grain wears, it continuously fractures to form sharp points and edges that slice through metal or hardwood, wear evenly and provide super-long life and consistency at any grinding pressure. This allows 3M™ Cubitron™ II belts, discs and bonded wheels to run cooler and keep on working—long after conventional abrasives have dulled, shelled, glazed over and been thrown out.

3M Cubitron II Product Categories

We keep a massive range of products including Cubitron II fibre discs (987C/787C for Stainless Steel and 982C/782C for Carbon and Mild Steel), 947A and theNEW 769FCubitron II flap discs, narrow Cubitron II belts 777F and 784F, powerfile / Dynafile Cubitron II belts, Silver and Cubitron II Cut-Off Wheels, Cubitron II Grinding Discs and Cubitron II 984F and 777F Roloc Discs.

3M Cubitron II - Pioneers of precision-shaped grain

The precision-shaped grain found in 3M™ Cubitron™ II Abrasives combines the advanced material properties of our original Cubitron grain with the precise microreplicated structures pioneered in 3M™ Trizact™ Abrasives. As the triangular shaped grain wears, it continuously fractures to form sharp points and edges.

Conventional ceramic abrasive grain is irregular and blocky in shape. Instead of a clean, machining action, the grain tends to “plow” through the metal, causing heat to build up in the workpiece and the abrasive — resulting in a slower cut, shorter belt life and undesirable effects, such as burnishing.

Cubitron II precision grain VS conventional grain

With decades of experience in ceramic, abrasive and microreplication technologies, 3M reinvented abrasives with 3M™ Cubitron™ II Products. The secret lies in the revolutionary precision-shaped ceramic grain technology pioneered by 3M. As the triangular shaped grain wears, it continuously fractures to form sharp points and edges that slice through metal or hardwood, wear evenly and provide super-long life and consistency at any grinding pressure. This allows 3M™ Cubitron™ II belts, discs and bonded wheels to run cooler and keep on working—long after conventional abrasives have dulled, shelled, glazed over and been thrown out.

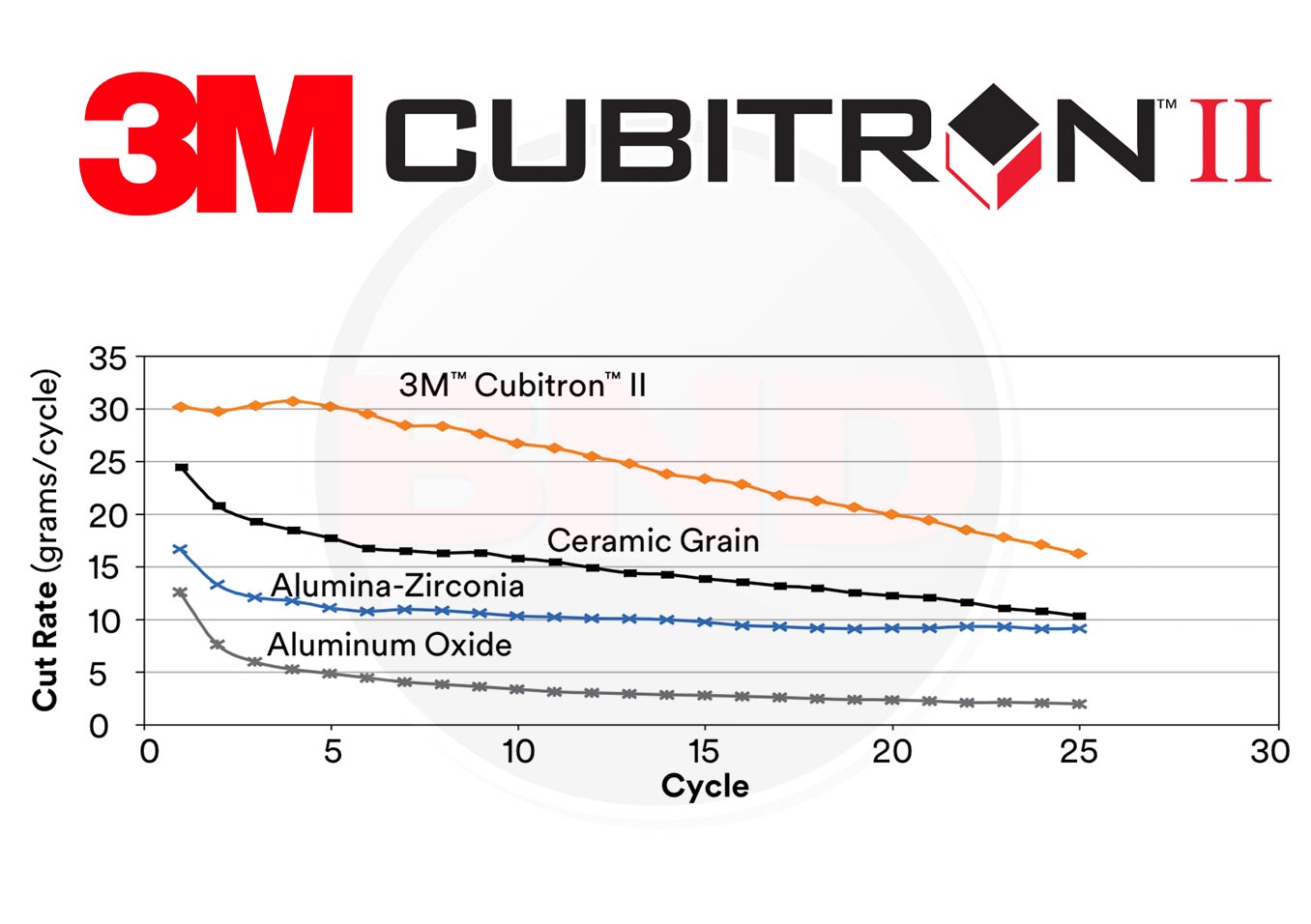

Why choose 3M Cubitron II over competitors?

3M Cubitron II abrasives not only last up to four times longer than conventional ceramic abrasive belts, but also cut faster throughout their life. This translates to more finished parts per belt per hour – and more profit to your bottom line.

But no abrasive belt or disc can live up to its full potential – unless your operators see the benefit. That’s where Cubitron II abrasives can really push your productivity over the top and save you money.

Request for 3M Cubitron II samples

Do you want to test the power of the 3M Cubitron II? Contact us to request for availability of free samples or order a small trial pack for your application!