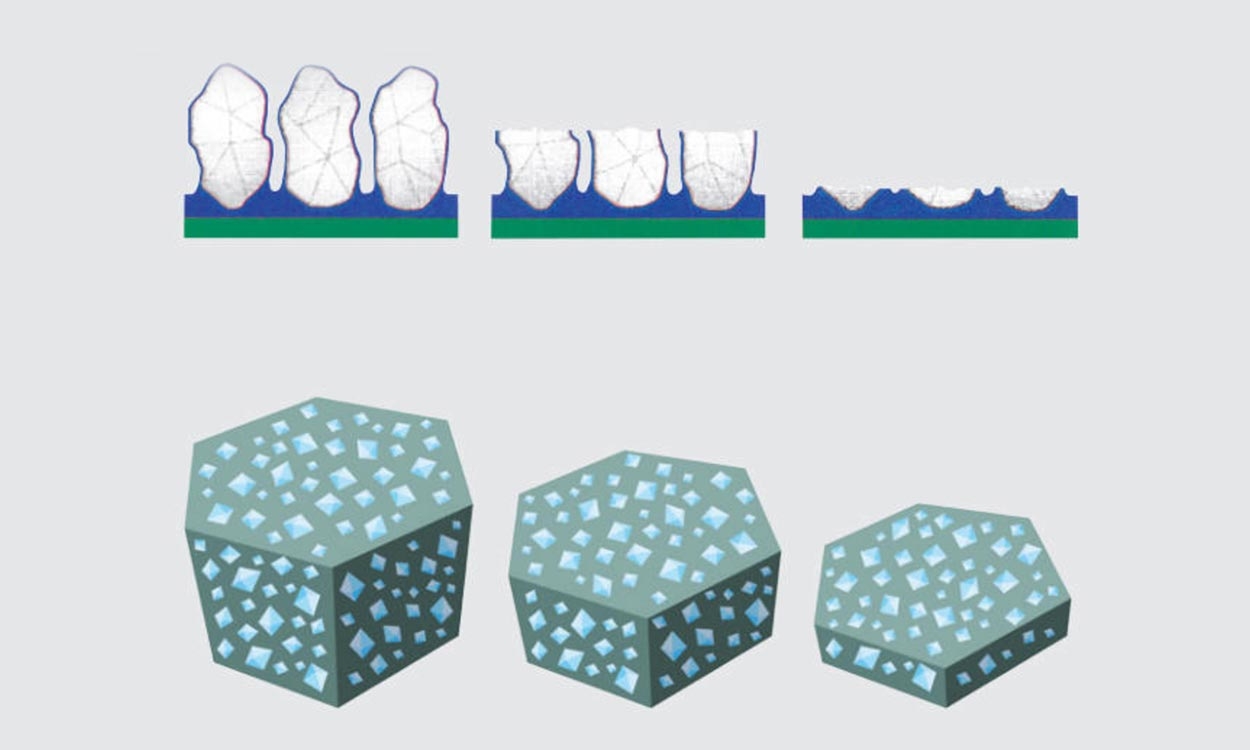

Conventional Abrasives start out sharp but dull quickly.

The three dimensional structure of 3M™ Trizact™ Abrasives contain multiple layers of mineral. As these structures wear, fresh, sharp mineral is constantly exposed to the workpiece, resulting in faster, more consistent cutting throughout the life of the belt.

Talk to a BND Abrasives Expert via our live webchat and we can easily help you select the grades you need to achieve the same finish you use with your conventional belts, or better!

• Reduce rejects. Trizact abrasives finer, more consistent finish cut the reject rate of an electroplating job- shop from 22% of parts to only 7% of parts.

• Increase labor productivity. An automotive component manufacturer experienced a 50% rise in parts finished per worker, since Trizact abrasives cut faster and eliminated several process steps.

• Improve capital equipment productivity. After switching to Trizact abrasives, a stainless steel fabricator produced parts in half as many steps as before, doubling output and eliminating a nagging production bottleneck.

Using Trizact belts means lesser belt changes and lesser grades to use to achieve the same or even better the finish.

To pick your Trizact grades, begin by selecting the starting grit for polishing that you currently use (usually P120 or P180) and look at your end-finish result grit that you want to achieve (i.e. grain finish / brushed finish = P800; or a mirror finish is around P2000). Select the grade equivalent from the 3M Trizact Grade chart provided here then select another one or two grades in-between those two to clean up previous scratch operations.

Example A (Brushed Finish P800)

Current process: Brush finishing Aluminium Oxide J-Flex Belts P120 - P180 - P240 - P400 - P600 - P800 (6 grits)

Suggested process: P120 belt, then A100 > A65 > A30 (4 grits/grades)

Example B (Mirror Finishing)

Current process: P120 - P180 - P240 - P320 - P400 - P600 - P800 - P1400 - P2000 (9 grits)

Suggested process: Trizact A160 - A100 - A45 - A30 - A16 - A6 (6 grits/grades)

BND Abrasives is an authorised 3M belt converter - meaning we can make the 3M Trizact, of any grade, into ANY SIZE of belt of your choice - File belt tool, backstand polisher, knife grinding belt grinder, even in most diameter disc form - you name it, BND can make it! Contact us via our live webchat or via our Contact Form with the size of your belt!

Committed to helping manufacturing companies gain a competitive edge, 3M Abrasive Systems offer expert knowledge and innovative abrasive technology and products like abrasive paper and abrasive discs. 3M Enables you to complete processes quickly, more cost effectively and safely.