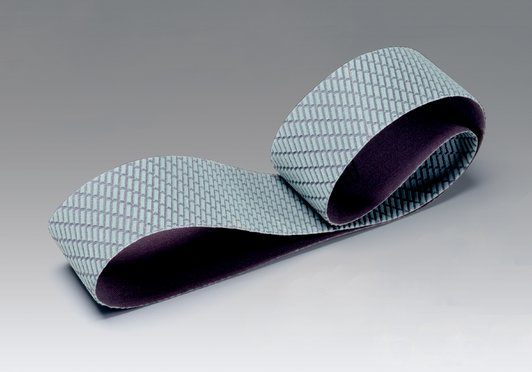

3M 337DC TRIZACT Abrasive Belts – 50mm x 2000mm Pack of 6 – (Various Grits Available)

£96.43£115.72 Ex VATInc VAT

- Details

- Additional information

- Downloads

Description

A Trizact™ abrasive belt on an X-weight backing used for Medium Pressure metal working: mill line removal, intermediate scratch refinement, consistent dimensioning, and consistent finishing applications. Use 3M™ Trizact™ Cloth Belt 337DC for consistent finishing in medium pressure metal working applications such as scratch refinement and dimensioning. Our belts feature macro-replicated abrasive on a flexible X weight backing, fast cutting premium aluminium oxide mineral and a grinding aid. They are designed for dry use only. Use 337DC belts for medium pressure metal work – such as mill line removal, intermediate scratch refinement, consistent dimensioning and consistent finishing applications.

Additional information

| Weight | 2.3 kg |

|---|---|

| Dimensions | 2000 × 50 cm |

| Brand | 3M |

| Width | 50mm |

| Length | 2000mm |

| Grit | A100, A160, A30, A300, A45, A65 |

| Mineral | Aluminium Oxide, Trizact |

| HS Tariff Code | 68051000 |

| Country of Origin | GB |

Downloads and Related Product information